A much more stable system can be found by using the following sequence, firstly the stator poles a1 and a2 are energised. The stator poles of b1 and b2 are then energised which pulls the rotor so that it is positioned between the stator poles of a and b. Following this the stator poles of a are de-energised and the rotor continues on to be aligned with the stator poles of b, this sequence continues through bc, c and ca before a full rotation has occurred. This sequence can also be reversed to achieve motion in the opposite direction.

The advantage of this operation over the simpler version is the stable operation that it provides. It also provides a well timed sequence as the timings of the phase being both on and off are equal rather than being at a 1:2 ratio as in the simpler sequence.

Control

The control system is responsible for giving the required sequential pulses to the power circuitry in order to activate the phases as required. There are two options for producing the sequence including a microcontroller to produce the signal or a timer circuit which could also produce the desired signal.

Timer

The use of a timer circuit would be very effective in producing the necessary signal in which to control the circuit. As the required signal is very simple it could easily be implemented by digital timer, such as the 555 timer. A digital timer is more precise than any other form of timer, such as a mechanical timer. With the widespread use of digital logic within integrated circuits the cost of these timers has reduced considerably. The latest controllers in use incorporate programmable logic controllers (PLC’s) rather than electromechanical components in its implementation. Within PLC’s, the timers are normally simulated by the software incorporated in the controller; the timer is therefore controlled by the software. There are obvious advantages to this system, although the control of a soft start could be hard to implement in this way.

Microcontroller

A microcontroller is ideal for this kind of application since it enables a very precise control of the phase activation timings. It also gives the possibility of implementing a soft start function in software form, in order to reduce the amount of hardware required. This is explained in the soft start section of this article.

Soft Starter

A motor soft stator is a device used to momentarily reduce the load and torque within the motor during starting. This reduces the mechanical stresses on both the motor and shaft. The reduced current demand lowers the stress on the conductor insulation. These motor soft starters can be either mechanical or electrical:

- Mechanical – come in the form of torque limiters utilizing clutches and various couplings,

- Electrical – these soft starters alter the power supply to the motor to reducing the torque and current demand. This is normally performed either by reducing the supply voltage, or controlling the frequency of excitation. Since switched reluctance motors are driven by a controlled pulsed supply, frequency control is an obvious choice in this case.

Depending on the application, the soft starting regime can be controlled with particular goals in mind, such as:

- Fixed start-up time - the start up will be controlled to achieve full speed within a fixed time

- Current limit - the motor current can be monitored and the start up controlled to keep it below a specified limit

- Torque limit - an intelligent starter can calculate the motor torque based on the current and voltage demand and control the start up to provide a constant starting torque.

Frequency Control

A software method of soft starting may also be achieved and be incorporated with a software implementation device for the control module. This can be done by slowly ramping the speed of the control pulses up to the final running speed. This has a major advantage of being easily controlled and changed at any point by simply altering the programming. By using this method the development time is reduced and the number of modules to implement is also reduced.

Using a C programming language, as with the control sequence above, the ramping up of the speed can be achieved. The method chosen to do so was the use of a counter, this works by instructing the program to run at different speeds as a certain number of counts have been passed. The coding for such use of a counter is shown below:

if (Counter<=20) //if counter is less than or equal to 20 then

Counter++; //counter plus one

else //if not

Speed = SOFT_START ; //speed = soft start

if (Counter<=30) //if counter is less than or equal to 30 then

Counter++; //counter plus one

else //if not

Speed = RUN1 ; //speed = run1

if (Counter<=40) //if counter is less than or equal to 40 then

Counter++; //counter plus one

else //if not

Speed = RUN2; //speed = run2

As can be seen above the actual speed at which it shall run is given a phrase and therefore needs to be defined at the initialisation stage. More stages are also required so that the motor shall run smoothly, any number of run speeds can be added to ensure that the ramping in speed is as smooth as possible. Alteration to the speed of ramping is also easy; there are two different methods in which this can be achieved. Firstly the defined speeds can be altered, or the actual size of the count required for the following step in speed can be changed.

The main advantage of such a soft start solution is the ease of alteration. The speed of each step can be altered easily and more steps added for smoother running of the motor.

Isolation

The electrical isolation of the control and power circuitry modules is very important and is used so that the control electronics are protected from any voltage fluctuations in the power circuitry. The major method of isolation used today are optoisolators, these isolators use short optical transmission paths to transfer a signal from one part of a circuit to another. The isolator incorporates a transmitter and a receiver, the signal therefore converts from electrical to optical before converting back to electrical thereby breaking any electrical connection between input and output.

Power Circuitry

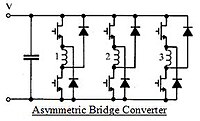

The most common approach to the powering of a switched reluctance motor is to use an asymmetric bridge converter.

There are 3 phases in an asymmetric bridge converter corresponding to the phases of the switched reluctance motor. If both of the power switches on either side of the phase are turned on, then that corresponding phase shall be actuated. Once the current has risen above the set value, the switch shall turn off. The energy now stored within the motor winding shall now maintain the current in the same direction until that energy is depleted.

This basic circuitry may be altered so that fewer components are required although the circuit shall perform the same action. This efficient circuit is known as the (n+1) switch and diode configuration.

A capacitor can be added to either configuration, and is used to address noise issues by ensuring that the switching of the power switches shall not cause fluctuations in the supply voltage.

No comments:

Post a Comment